One of the first questions many people have when building a 3D printer is, “How much does it cost?” The answer is surprisingly different for each printer. While the overall price for building a 3D printer will depend on the parts used, you can expect to spend as much as $2,000 on materials. This includes filament, Nylon powder, and printing services. Below we will look at what these materials will cost you and how to budget accordingly.

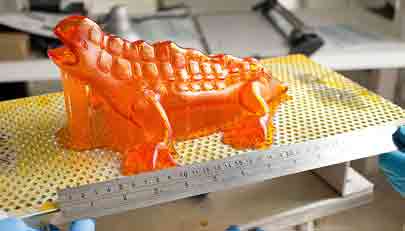

Cost of 3D printing resins

The cost of resins for 3D printers can vary greatly. The cheapest resins are typically cheaper than those for filament. The majority of resins, however, cost at least a couple of dollars per gram. For example, Filamentum sells their filament for $35 per kilogram. In contrast, the price of ASA resin is slightly higher, at about $35 per gram. For most users, the price of ASA filament is the same as that of filament.

A report focusing on the global 3D printing resins market will provide a comprehensive analysis of the market. It will detail the key statistics, market size, market segmentation, and competitive landscape. The report will also provide insight on emerging opportunities and future technology. The report will also assess the attractiveness of the different segments. It will identify and analyze market trends that will drive the market in the near future. And finally, it will provide an opportunity map of the global 3D printing resins market.

Cost of filaments

The cost of filaments when building a 3D printing machine can be overwhelming, especially if you are just getting started. Filaments can range in price from cheap to expensive depending on the material. Usually, you can buy no-name filament for under $20, or even less! But these filaments typically have filler materials, an inconsistent diameter, and poor spool winding. That means you might end up with a failed print that costs more than you first expected.

There are many different types of filaments available, and the price can range greatly depending on which material you choose. For example, if you’re planning to make custom parts for your 3D printer, it’s probably best to stick with a basic PLA or ABS filament, as these are the cheapest and have the most benefits. There are also specialty materials you can use, but these are generally more expensive.

Cost of Nylon powder

The cost of Nylon powder for building 3d printing service varies depending on the type of Nylon polymer used. The cheapest plastic materials include Multi Jet Fusion PA12. For those who are looking for the most affordable plastic materials, however, the price per kilo will be significantly higher. The most expensive materials are usually made of Nylon, as this is the most commonly used type of plastic.

The cost of Nylon powder for building a 3d printer varies, but generally runs around $50 to $60 per kilogram. The same material can also be filled with other additives to improve the mechanical and thermal properties. Some of these additives include carbon fibers, glass fibers, and aluminium. However, materials filled with these materials are typically more brittle and have highly anisotropic properties.

Cost of printing services

The cost of printing services for a 3D printer is determined by a number of factors, including the material, printer type, and overall complexity of the project. There is also a fixed cost for staff time and support, and the cost of filament increases with size and density. Generally, the larger the 3D model, the more filament it will require, and the higher the cost. Craftcloud makes it easy to get multiple quotes on printing services.

Conclusion:

If you own a 3D printer, you can save a significant amount of money on printing materials and services. The first step is to choose the material that is the most cost-effective. For most parts, a powder will be the least expensive material. However, if you choose to use a filament, you may end up paying more for the material itself. Luckily, powders are not as expensive as filament, which makes them an excellent option for a home printer.

Jerry Martinez is a professional artist. He lives in California with his family. Throughout his life, he has always been captivated by images. Naturally, he was drawn to art. So he opted to take his Bachelors Degree in Fine Arts from Otis College of Art and Design. After completing his degree, He concentrated even more into his art practice. He is a father of three children, ranging in age from 3 to 12 years old. They love outdoors activities; biking, camping, walking and playing football. Jerry Martinez is a music lover and love to listen to metallic songs.