As you walk into a modern factory in Guangzhou, China, you’re immediately struck by the hum of machinery and the sight of rows upon rows of precision-crafted vacuum forming machines. But how did this city become the go-to destination for elite plastic manufacturing? It’s not just a coincidence. Guangzhou’s rise to global leadership is a story of strategic planning, cutting-edge infrastructure, and a highly skilled workforce. And it all started with a series of deliberate decisions by the government and industry leaders. Now, you’re probably wondering what exactly those decisions were.

Strategic Government Support

The government plays a crucial role in fostering the growth of the vacuum forming plastic manufacturing industry through strategic support. You see, Guangzhou SME Plastic Corp, a leading vacuum forming manufacturer, has benefited greatly from government initiatives that provide financial incentives, tax breaks, and access to low-interest loans. These incentives have enabled thermoforming companies like Guangzhou SME Plastic Corp to invest in research and development, upgrade their technology, and expand their production capacity.

As a result, they can offer a wide range of vacuum forming solutions to clients, from packaging materials to automotive components. The government’s strategic support has also helped to create a favorable business environment, with streamlined regulations and efficient logistics. This has made it easier for vacuum forming manufacturers to operate and thrive in the region. By providing this support, the government has helped to establish Guangzhou as a hub for vacuum forming plastic manufacturing, attracting investment and talent from around the world.

Advanced Manufacturing Infrastructure

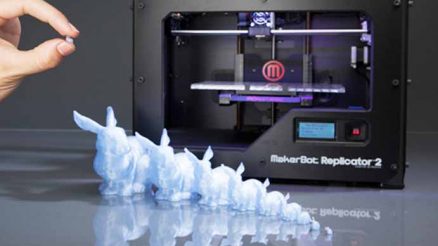

Within Guangzhou’s thriving vacuum-forming plastic manufacturing ecosystem, you’ll find state-of-the-art facilities equipped with cutting-edge machinery and technology, thanks to significant investments in advanced manufacturing infrastructure. This infrastructure enables vacuum forming suppliers to produce high-quality vacuum-forming products, such as automotive parts, medical devices, and packaging materials, with precision and efficiency. The advanced manufacturing infrastructure includes computer-aided design (CAD) systems, computer numerical control (CNC) machining centers, and advanced thermoforming machines.

These machines can produce complex geometries and intricate designs, making Guangzhou’s vacuum forming products highly sought after globally. In addition, the infrastructure supports the development of innovative materials and processes, allowing thermoforming manufacturers to stay ahead of the curve. The advanced manufacturing infrastructure in Guangzhou has played a vital role in establishing the city as a global leader in vacuum forming plastic manufacturing, attracting international clients and driving economic growth.

Skilled Workforce and Training

As you explore into Guangzhou’s vacuum forming plastic manufacturing ecosystem, you’ll discover a skilled workforce that serves as the backbone of this thriving industry. This skilled workforce has been developed through rigorous training programs that focus on the intricacies of the vacuum forming process. Manufacturers in Guangzhou invest heavily in training their employees to certify they possess the expertise required to produce high-quality custom vacuum forming products.

The thermoforming service providers in Guangzhou have a deep understanding of the materials and techniques involved in the vacuum forming process. This expertise enables them to optimize production workflows, resulting in faster turnaround times and reduced costs. Additionally, the skilled workforce is well-versed in quality control measures, guaranteeing that every product meets the highest standards of quality and precision.

The availability of a skilled workforce has been a key factor in Guangzhou’s emergence as a global leader in vacuum forming plastic manufacturing. This talent pool has enabled manufacturers to focus on innovation and expansion, driving growth in the industry. As demand for custom vacuum forming products continues to rise, Guangzhou’s skilled workforce is poised to meet the challenge, delivering high-quality products that meet customers’ exacting standards worldwide. You can visit https://smeplastic.com/ to get more information about vacuum forming plastic.

Investment in R&D and Technology

Several key players in Guangzhou’s vacuum forming plastic manufacturing sector are driving innovation through substantial investments in research and development (R&D) and cutting-edge technology. You’ll notice that these companies are constantly exploring ways to improve their thermoforming process, enhancing the quality and efficiency of their vacuum forming plastic products. As a result, Guangzhou-based vacuum forming companies can now produce complex, high-precision parts with reduced lead times and costs.

Investments in advanced machinery and equipment have also enabled thermoforming suppliers to expand their product offerings and cater to diverse industries. For instance, you can find vacuum forming companies in Guangzhou that specialize in producing medical device components, automotive parts, and even aerospace components.

Their ability to adapt to changing market demands and customer requirements has contributed notably to Guangzhou’s emergence as a global leader in vacuum-forming plastic manufacturing. By staying at the forefront of technological advancements, Guangzhou’s vacuum-forming companies are poised to maintain their competitive edge in the global market.

Competitive Pricing and Logistics

Thanks to their strategic location and access to a vast supply chain network, Guangzhou’s vacuum forming plastic manufacturers can offer competitive pricing. This enables them to keep production costs low, which is then passed on to you as the customer. Companies like Guangzhou SME Plastic Co Ltd, a leading custom thermoforming supplier, can offer affordable rates without compromising on quality. Their vacuum forming service guarantees that thermoforming products are manufactured efficiently, reducing waste and excess material usage.

Logistically, Guangzhou’s proximity to major ports and transportation hubs makes it ideal for exporting thermoforming products to global markets. Manufacturers can use streamlined shipping processes, reducing lead times and costs. As a result, you can expect faster delivery times and lower shipping costs. With competitive pricing and efficient logistics, Guangzhou’s vacuum forming plastic manufacturers have established themselves as a reliable and cost-effective option for businesses seeking high-quality thermoforming products.

Conclusion

As you examine the factors behind Guangzhou’s rise to dominance in vacuum forming plastic manufacturing, a theory emerges: strategic government support is the linchpin that sets off a chain reaction of advantages. With favorable policies, advanced infrastructure and a skilled workforce naturally follow, further fueled by investments in R&D and technology. The resulting competitive pricing and logistics solidify Guangzhou’s position as a global leader, making this theory a tangible reality.

Jerry Martinez is a professional artist. He lives in California with his family. Throughout his life, he has always been captivated by images. Naturally, he was drawn to art. So he opted to take his Bachelors Degree in Fine Arts from Otis College of Art and Design. After completing his degree, He concentrated even more into his art practice. He is a father of three children, ranging in age from 3 to 12 years old. They love outdoors activities; biking, camping, walking and playing football. Jerry Martinez is a music lover and love to listen to metallic songs.